Hemming

Joining inner and outer panels is a critical process that significantly affects function and vehicle appearance.

With decades of experience in the art + science of hemming, our team works directly with vehicle OEM’s and suppliers to make sure the final closure design can be manufactured without compromise to outstanding quality.

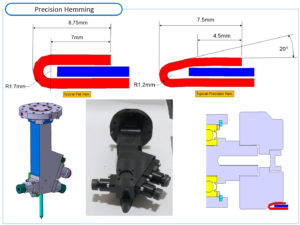

Our dedicated team of hemming experts get involved in the early stages of product development in order to ensure optimum results. Complete flange and snap studies are conducted in 3D so potential challenges are overcome in the virtual space prior to die development. The final Hemming tools are designed to suit the recommended flange lengths and angles from the dies.

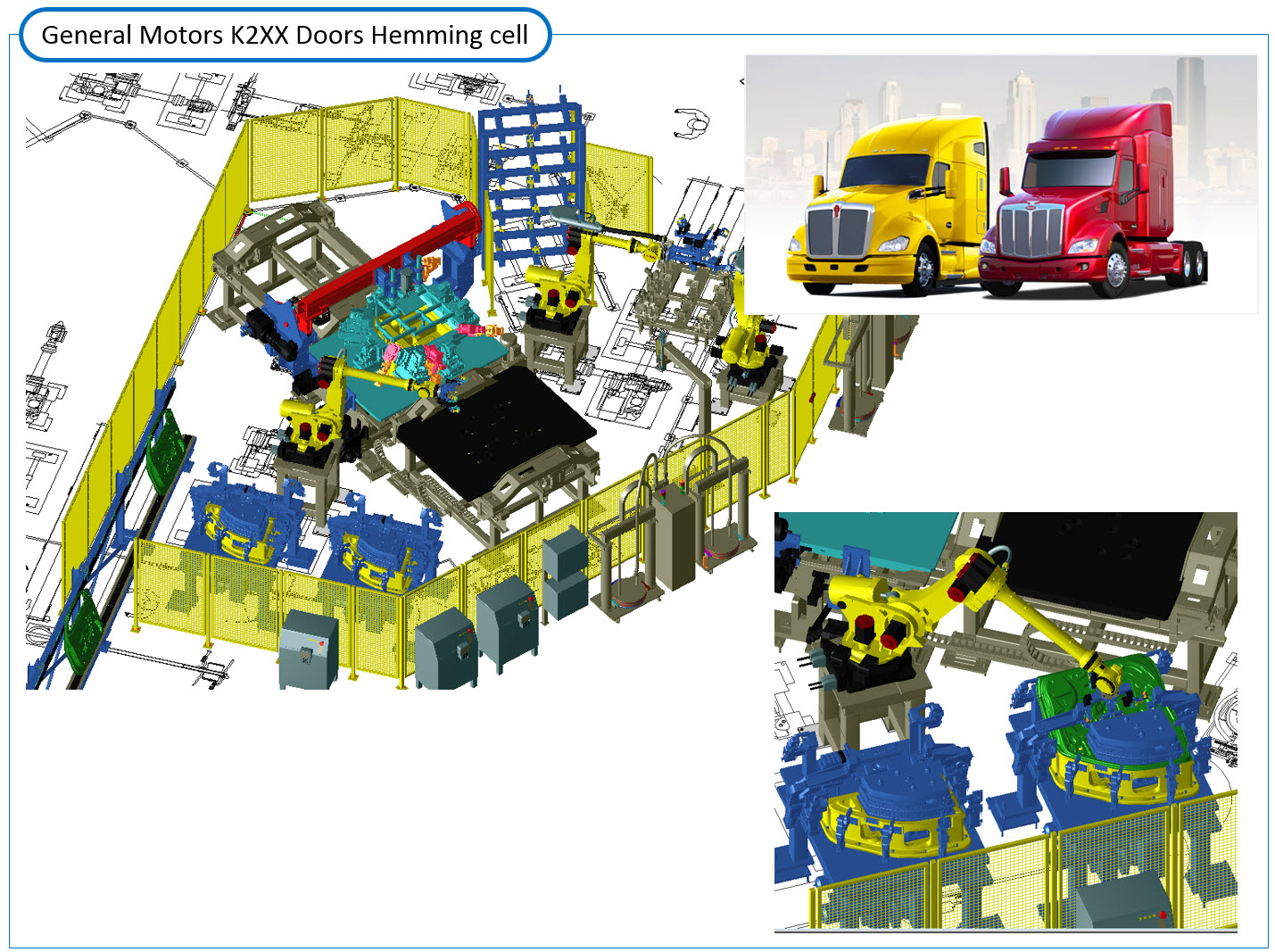

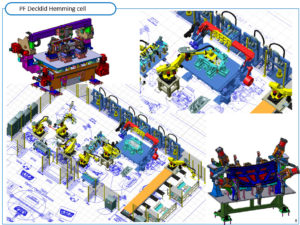

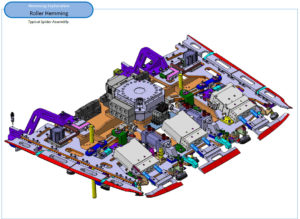

Robotic Roller Hemming

Roller hemming combines standard industrial robots equipped with a standard roller hemming head that follows the contour of the outer flanges of a sheet metal component, optimally hemming it over an inner panel which is precisely nested in a die. Our flexible process offers numerous advantages over traditional techniques including reduced capital investment costs with superior dimensional quality.

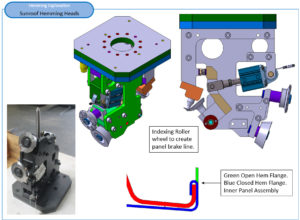

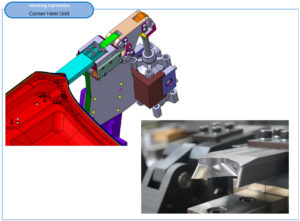

Roller Hemming Heads

Our hemming engineers have designed and developed many types of Roller Hemming Heads to use for different applications. These include the following types

- Basic heads (single roller, no load monitoring)

- Flexible heads (multiple rollers with load monitoring)

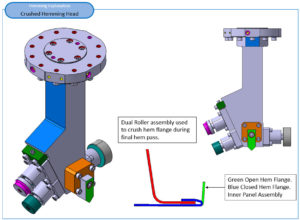

- Parallel Roller Heads (to create crushed hem flanges)

- Tin Can Roller Heads (to create panel break lines when flanges are open 180 degrees off die)

- Custom head designed for unique applications

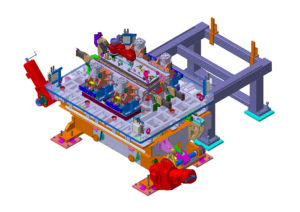

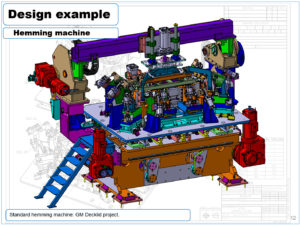

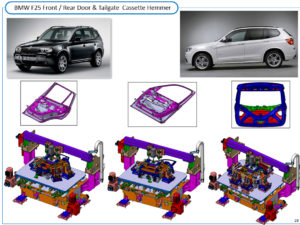

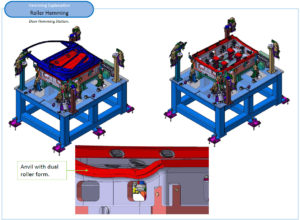

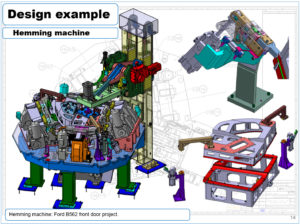

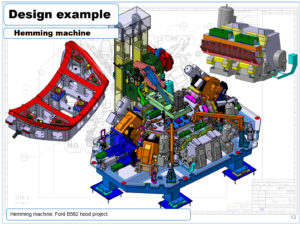

Press Hemming

Our press hemming solutions offer great speed and deliver high quality results every time. The standard press hemmers are flexible and can be used for different models or variants. The Hemming Die Sets are the dedicated part to the machine and are compatible with hydraulic and electric presses. The use of standard sub-assembled components reduces the overall manufacturing cost.

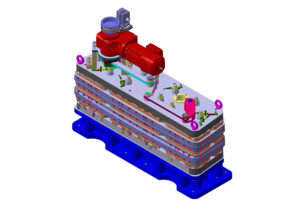

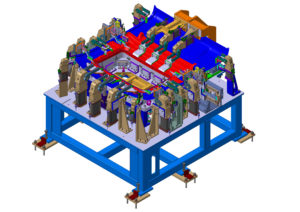

Internal Hemming

As part of our press hemmer we have developed an Internal Hemmer solution for internal apertures of doors or sunroofs. The internal head sits within the door window aperture and expands by using a motor to operate linkages, these connect to the forming steels which slide into position.