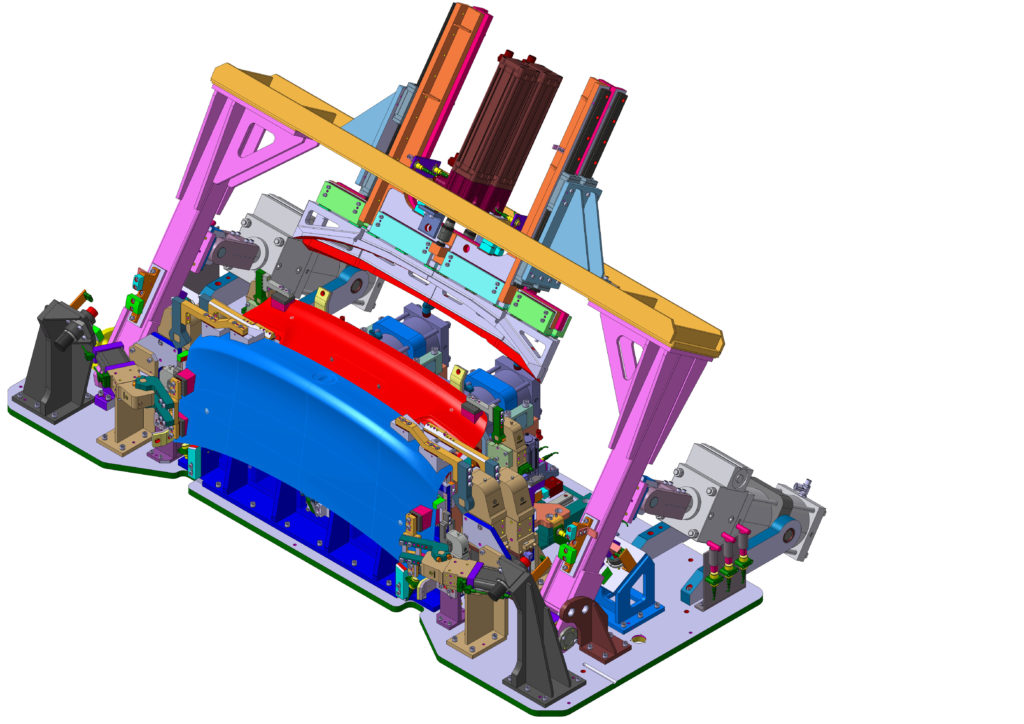

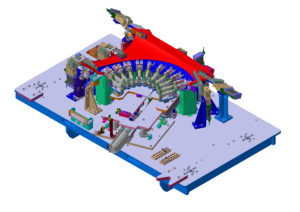

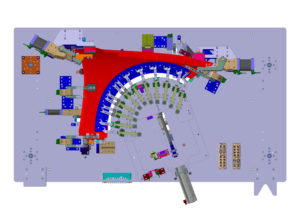

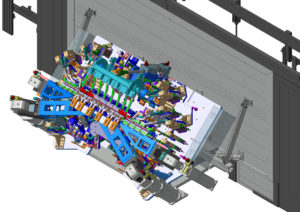

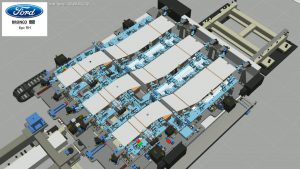

Laser Tooling

From automotive to aerospace – laser welding is suitable for many different areas of application.

The technology offers decisive advantages in the production of medium and large batch sizes. Laser Welding technology is becoming more common in joining Class A Outer panels like liftgates and Decklids.

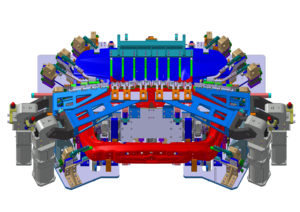

The Technology

During laser welding, the laser heats the material to melting temperature. The beam is focused by means of optics. The weld seam is created by the relative motion between the laser beam and the workpiece. SMC provides individual solutions and all types of production technology for laser welding. This ranges from the modular robotic cell to the fully-automated system – also in conjunction with other joining technologies, such as sealing or spot welding. The tooling design for Laser welding cells is very specific and important. Our expertise and experience in tool design is crucial to obtain a quality joint.