Virtual Commissioning

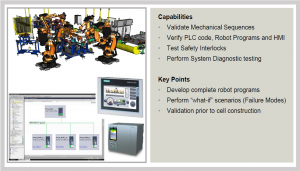

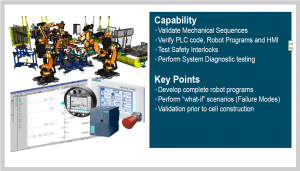

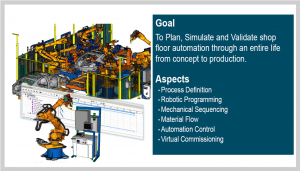

Virtual commissioning is the practice of replicating the behaviour of a physical manufacturing environment with a software system. The ultimate goal of the emulation is to provide an environment for the manufacturing automation controls engineer to validate their PLC (Programmable Logic Controller) ladder logic and HMI (Human Machine Interface) files prior to system debug in the manufacturing production environment.

The benefits of Virtual Commissioning?

Today’s highly automated and flexible manufacturing systems include sophisticated tooling, robots, transfer lines and other safety equipment and they are all controlled by programmable logic controller (PLC) programs. Virtual commissioning allows one to debug PLC code in a virtual environment before downloading it to real equipment. By simulating and validating automation equipment virtually, one can confirm that they will work as expected and significantly reduce system startup time. Manufacturers who have used virtual commissioning have reported reductions in engineering time by as much as 30 percent.

How does Virtual Commissioning work?

In a virtual commissioning process, engineers build a 3D virtual model of the system including all kinematic and static equipment, using simulation software. The 3D software is connected to the PLC and HMI, wherein the actual code runs. The virtual 3D system mimics the physical environment very accurately, so that the engineers can run all test and debugging procedures, just like they would in real life.